This post was sponsored by Salveo – cord blood.

I have done a few posts on stem cells this year and why I think that it is important to invest in it so writing this post breaks my heart a little – because I had such high expectations for my procedure that happened in June.

Before I go any further I just want to let you know that I don’t blame Salveo or my doctor for this and I know that they both tried their best to get what they could out of the sample they had.

I assumed that everything would go the way that it was supposed to on the day in the theater because what could really go wrong? This procedure has been done several times before, right?

Stem cells storage isn’t exactly cheap in South Africa so when you invest in it, you are hoping that it works 100%.

I for one did not expect the shocking results that we had received a few days after my baby was born – but it was too late…

As a parent, there is nothing that you can really do to change anything in the collection process. However, you can make sure that your doctor and his team are educated enough about the procedure especially if they have not done it before.

There’s only ONE opportunity to get this right! It cannot be done again.

There are three main reasons why a cord blood collection may not be successful:

- An insufficient amount of blood may be collected.

- A lower-than-usual amount of blood may be collected and the stem cell count in the collection is very low.

- The sample may be contaminated with a bacteria at the time of the collection.

In our situation, it was number 2 – a low number of stem cells in the sample collected.

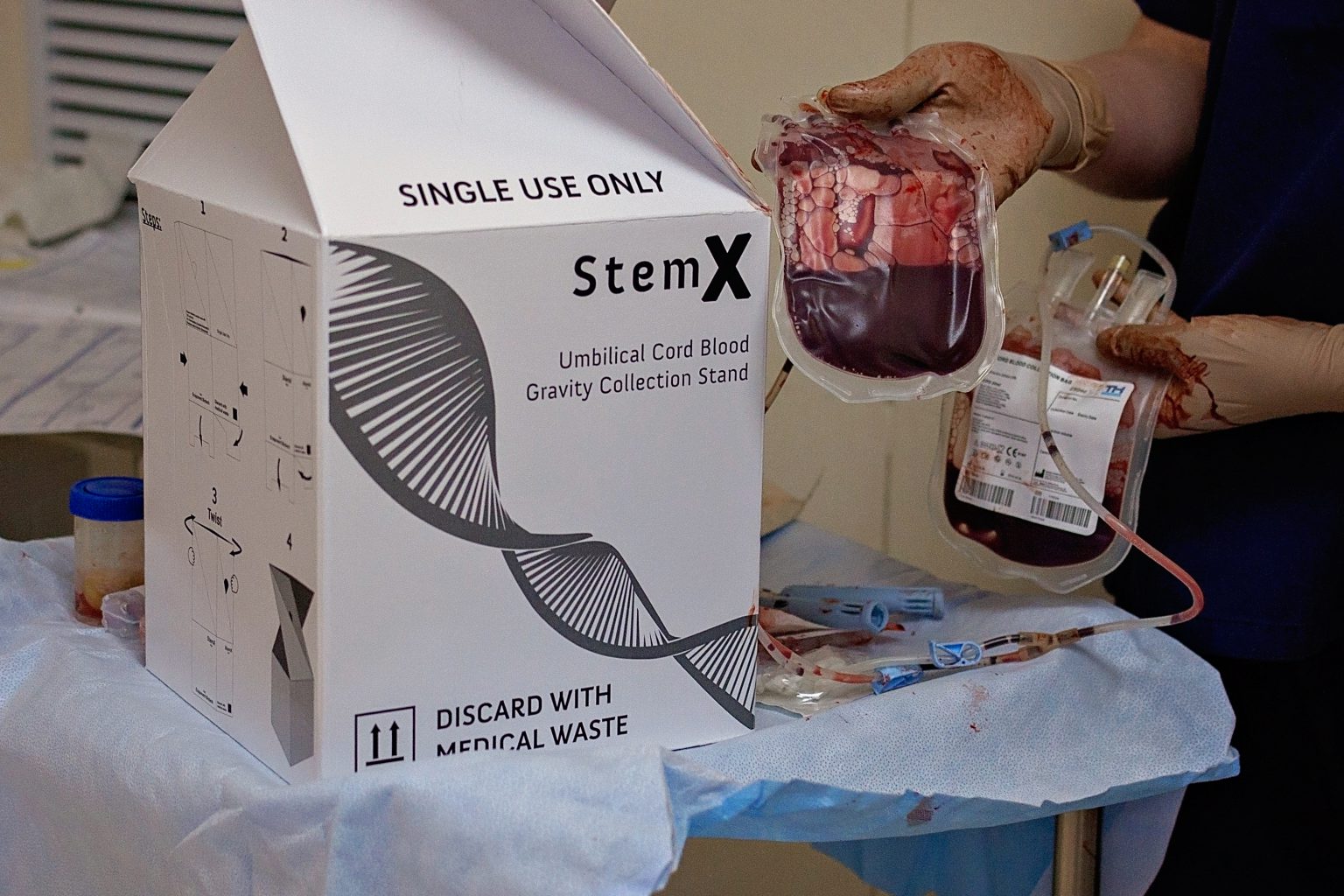

In order for a cord blood stem cell transplant to be successful, there needs to be a sufficient number of stem cells in the blood collected from the umbilical cord. The number of stem cells is, in general, directly proportional to the amount of blood collected. Usually, at least 80ml of blood can be collected from the cord of a full-term infant from an in-utero collection. Additional ex-utero collection can be performed to increase the total volume collected.

In our situation, only 17ml of umbilical cord blood was submitted and the number of haematopoietic stem cells (blood producing stem cells) (CD34+ cells) in the collection was 214 832. I know, that might sound foreign to you but what that basically says is that… it’s not enough but they can work with it if you really want them too.

Umbilical cord blood contains potentially lifesaving hematopoietic (blood) stem cells. When used in hematopoietic stem cell transplantation, the umbilical cord blood offers several distinct advantages over bone marrow or peripheral stem cells.

Honestly, I was a bit shattered when we got the results back because I felt as if enough was done in the theater to make sure that we collected the amount that we needed. It was only afterward that I realized that overthinking it would just drive me crazy! I needed to move on.

According to the Salveo website, there are a number of medical and physiological reasons why a sufficient volume of umbilical cord blood is not able to be collected. This may occur, for example, in low birth-weight infants and in situations of delayed clamping of the umbilical cord.

Honestly, I still don’t know what went wrong in my procedure but I’m not going to blame anyone for it. I think I learned a lot from this journey.

Various blood tests, stem cell counts, and blood cultures are performed, on Salveo’s behalf, by a Private Pathology Laboratory before they collate the results, particularly the blood culture results, and contact you which is approximately 10 days after the birth of your baby.

Salveo gave me an option of a refund or an adjusted fee since the cord blood collection was not successful. My husband and I decided to store what we have anyway because I think every drop matters. I pray we would never need to use it, but I am glad we do have something stored.

It’s so important to educate yourself especially about the WHAT Ifs, terms & conditions etc. Don’t be afraid to ask your doctor or stem cell storage company questions even in the theater.

If you would like any additional information or would like to discuss the collection, processing and testing procedure, please contact Cryo-Save or Salveo on 087 8080 170.

26 comments

Scrap copper buyers Copper scrap importers Scrap copper reclamation

Copper sheet and plate recycling Copper scrap volume Environmental benefits of Copper scrap recycling

Copper alloy identification Copper scrap melting Waste water treatment in copper recycling

Aluminium scrap warehousing Scrap aluminium upgrades Aluminium waste disposal industry

Metal treatment services Ferrous material recycling agreements Iron scrap reclamation and reuse

Ferrous scrap treatment, Iron scrap reclamation center, Scrap metal weighing services

Metal reclamation and regeneration Ferrous metal reclaiming yard Iron and steel reclamation

Ferrous material distribution network, Iron scrap recovery solutions, Scrap metal repurposing technologies

Metal reclaiming and reprocessing facility Scrap aluminium material traceability Aluminium scrap cutting

Scrap metal transportation logistics, Scrap aluminum cable market analysis, Metal scrap refurbishing services

Metal refuse reclamation Aluminium recycling Scrap aluminium export regulations

Metal waste repurposing services, Aluminum cable scrap buyer, Metal waste transportation

Metal recovery yard collection Aluminium scrap electroplating Aluminium scrap resource optimization

Recycling Sustainability, Recycling methods for aluminum cable scrap, Industrial scrap metal buyers

Metal scrap recovery depot Ferrous material recycling client satisfaction Iron scrap compaction

Ferrous material pulverization, Iron scrap recycling industry, Scrap metal reclamation processing

Metal recycling reclamation Ferrous material recycling industry analysis Iron scrap treatment

Ferrous material recycling environmental compliance, Iron and steel reclamation, Scrap metal reclamation and reutilization services

Metal reclaiming Yard Aluminium recycling service providers Scrap aluminium repackaging

Metal reclamation company, Aluminum cable recycling, Scrap metal refurbishment

Metal reclamation and recovery services Ferrous material recycling partnerships Scrap iron recovery services

Ferrous material industry updates, Iron scrap resale, Metal recovery and repurposing

Scrap metal sustainability Aluminium scrap purity standards Aluminium reprocessing technologies

Metal recyclable waste management, Aluminum cable recycling centers, Scrap metal end-of-life management

Metal scrap processing Ferrous material market outlook Iron and steel reclaiming and recycling

Ferrous material permits, Iron scrap retrieval yard, Metal waste reclaiming solutions

Scrap metal reclamation and recycling Aluminum scrap processing Scrap aluminum alloys

Metal scrap reutilization, Scrap aluminum cable buyers, Scrap metal recycling and reclamation

Scrap metal repurposing center Ferrous material recycling processing equipment Iron scrap reusing

Ferrous material equipment maintenance, Iron and steel recycling plant, Metal waste recovery

Recycled copper ingots Copper billet production Copper alloys

Metal reclaiming process, Copper smelting process, Scrap metal reclaiming and recycling yard

Copper scrap handling Copper is used for most electrical wiring for several reasons. First and foremost, copper is an excellent conductor of electricity. This means that electrons can flow freely through copper, making it an efficient material for electrical wiring. Additionally, copper is very ductile, which means it can be easily bent and shaped without breaking. This makes it a versatile material that can be used in a wide variety of electrical applications. Copper is also very durable and long-lasting. It is resistant to corrosion, which means it can withstand exposure to moisture and other environmental factors without deteriorating over time. Copper wiring can also withstand high temperatures, making it suitable for use in high-heat environments such as industrial machinery or electric motors. Another advantage of copper wiring is that it is very easy to work with. It can be easily soldered or brazed, and it can also be crimped or twisted together to form connections. Copper wiring is also very easy to terminate, which means that it can be connected to other components or devices easily and securely. Finally, copper wiring is also very cost-effective. While initial costs may be higher than other materials, the long-term benefits of copper wiring make it a more economical choice over time. Its durability and low maintenance costs mean that it can last for many years without needing to be replaced or repaired. Overall, the combination of copper’s excellent conductivity, ductility, durability, ease of use, and cost-effectiveness make it the ideal choice for most electrical wiring applications Scrap metal reclaiming center Copper scrap emergency protocols Copper scrap environmental impact Copper scrap legal requirements Copper recycling facility Metal waste melting

Copper tube recycling Copper is a vital component of modern technology. It is used in everything from electrical wires and motors to wind turbines and solar panels. With the world turning towards renewable energy, the demand for copper is set to soar. However, there are concerns that the supply of copper may not be able to keep up with demand. One reason for these concerns is that the largest copper mines in the world are aging and becoming depleted. Copper mines require significant capital investment and can take years to develop, which makes new mines risky for investors. Additionally, mining copper can have negative environmental impacts, especially in areas with delicate ecosystems. Another factor affecting the supply of copper is geopolitical tensions. Major copper-producing countries such as Chile and Peru have experienced political instability, which has disrupted copper production. In addition, there are concerns that increasing demand for copper could lead to resource nationalism, where countries restrict their exports of the metal to protect their domestic industries. The shortage of copper could have serious implications for the energy transition. Renewable energy technologies require significantly more copper than fossil fuel-based technologies. For example, an electric car requires four times more copper than a conventional car, and a wind turbine requires nine times more copper than a natural gas-fired power plant. To address the looming supply gap, there are several options. One is to increase recycling of copper. Recycling brass, which is made up of copper and zinc, is relatively straightforward, but recycling cables and other copper-containing products can be more challenging. Another option is to develop new copper mines and expand existing ones. This requires significant investment and regulatory approvals. In conclusion, the future of copper is uncertain. The supply of copper may not be able to keep up with demand, which could have significant implications for the energy transition. It is up to policymakers, investors, and industry leaders to take action to address this issue and ensure a sustainable future for copper and the technologies that rely on it Scrap metal waste Scrap Copper sorting Copper scrap pricing Copper scrap revenue optimization Copper scrap refining Metal waste reclamation

Metal waste reusability Ferrous material processing efficiency Iron scrap reclaiming and reprocessing

Ferrous material supply chain optimization, Iron scrap processing machinery, Scrap metal salvage

Copper scrap track and trace Copper scrap packaging techniques Scrap metal recovery solutions

Copper cable price per pound, Scrap metal export documentation, Scrap Copper disposal

Metal recovery and reclaiming center, Copper scrap recovery methods, Copper cable recycling services, Metal recovery and recycling solutions

Scrap metal recycling incentives Metal scrap yard services Iron scrap export procedures

Ferrous metal recycling benefits, Iron reclamation, Metal waste recycling services

Scrap metal recycling incentives Ferrous material recycling air quality control Iron reprocessing yard

Ferrous recycling center, Iron reclaimer, Metal scrap recovery and reclamation

Scrap metal salvage Construction ferrous metal recycling Iron scrap disassembling

Ferrous metal recycling services, Iron processing, Scrap metal recycler

Non-ferrous metal recycling Ferrous material recycling research Iron scrap residue

Ferrous material processing efficiency, Iron repurposing and recycling, Scrap metal volume assessment